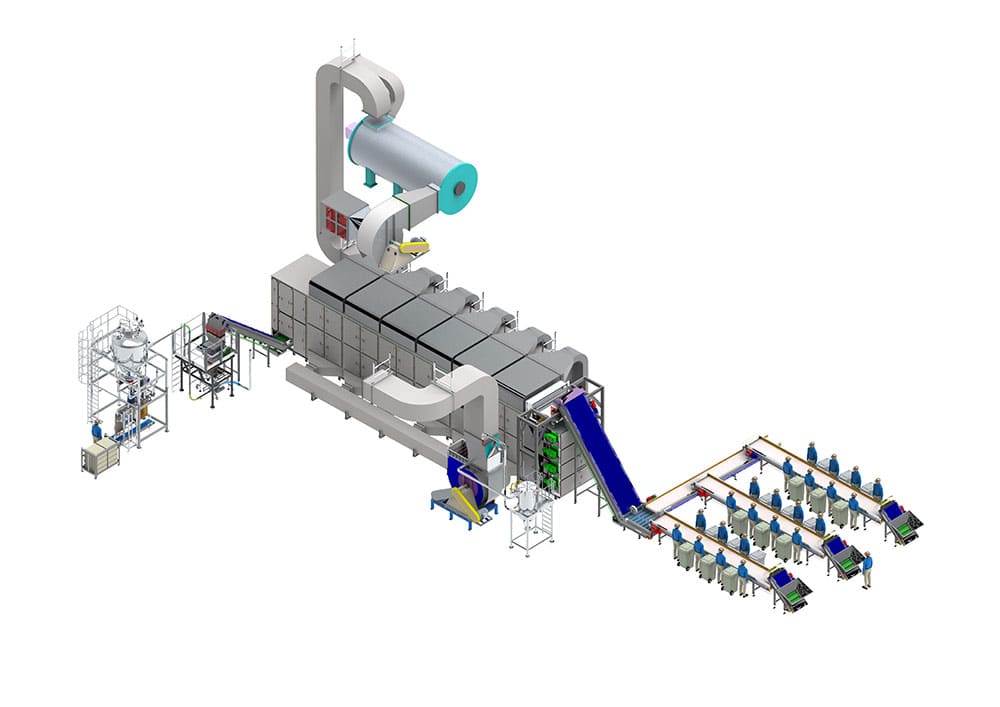

Total Integration From Sorting to Packaging via Conveyors, Buffer Storage and Packaging.

Biomass Pre-Processing Solutions

Increase yield and extraction efficiency with our complete solutions for biomass pre-processing.

Pre-processing retains Biomass profile, improves yield & ensures purity of end products. Significantly improve your product quality with our robust & automatic pre-processing solutions custom designed for your requirements.

-

01. Sorting Conveyors:

Complete wash-down trough belt conveyors help in sorting and cleaning of biomass by operators.

-

02. Conveyorized Drier:

7 levels of biomass drying via convective drying to ensure precise regulation of temperature & moisture, resulting in no loss in morphology.

-

03. Continuous Biomass Milling & Weighing-Filling:

Continuous mill reduces dried biomass particle size, metering into a weighed storage container. An ideal biomass size ensures efficient extraction.

Technical Specifications

| Parameter | Value |

|---|---|

| Capacity | 200 / 500 / 700 / 1000 |

| Biomass Particle Size | 6 to 8 mesh, 2 to 4 mm (Customizable) |

| Biomass Moisture Content | 6 to 8 % (Adjustable) |

| Sound Level | Below 75 dB |

| Footprint | Customizable as per facility layout |

| Power Consumption | 175 kW |

| Dryer Heat Capacity | 550,000 kcal/hr |

| Dryer Air Temperature | 65°C to 70°C |

| Dryer Air Velocity | 0.5 to 1 m/s |

| Air Circulation Rate (Overall) | 40,000 m3/hr |

System Features

Nutrient Retention Fine grinding without excessive heating.

Minimal Biomass Loss Biomass Recovery System, Trough Conveyors.

Energy Efficiency 80% Dryer air recirculation.

Fuel Flexibility Gas / Electricity / High Speed Diesel (HSS).

Precise Parameter Regulation Uniform, multilayer heating for close temperature and moisture control.

Intelligent Automation Single point HMI/SCADA monitoring and control.